Results from the largest nationwide survey on the use of precision technology, conducted by Hutchinsons, has revealed detailed insight into the level of uptake of precision farming across UK farms, how growers use precision farming systems and how they intend on using them in the future.

Over the last decade the interest in precision technology for more accurate machine steering, controlling how we apply products to the fields and field mapping & recording has undoubtedly increased says Oliver Wood, precision technology manager with Hutchinsons.

The objective of the Hutchinsons survey was to test these theories and to provide some definition to how farmers are using precision technology on farm and where they see future developments.

With over 1,100 responses from farms of all sizes and from across the UK, the results showed that 70% of respondents already use some form of precision technology. However, such is the interest in the subject that 30% of all respondents to the survey currently have no precision technology on their farms but wanted to engage with the subject.

Despite current low commodity prices, over half of all respondents indicated that they are planning on expanding their precision agronomy operations in the next 12 months. Farm size is clearly less of a barrier to the increasing interest in precision technology with 42% of those farming less than 300 hectares.

However the survey shows that as farms get bigger, more of them are engaging with precision technology systems. GPS steering was unsurprisingly by far the most popular use of precision technology with 55% of those surveyed already using it across their farms - most likely due to the benefits being clearly visible and now widely understood.

GPS steering was also the most popular development on smaller farms, although Mr Wood notes that for farms under 300 ha there is a much smaller difference between those using GPS steering and variable product applications (fertiliser, seed, crop protection products).

“This might indicate that these smaller businesses are utilising the variable application controls that exists in most GPS steering control boxes, making the most of their large capital outlay.”

With regards to specific detail on how variable rate applications were used the survey confirmed that base fertiliser was well ahead of nitrogen, seed and other crop protection products.

“Growers have clearly accepted this opportunity taking advantage on savings to be made but with a focus on boosting output. The second hand machinery market is also making some of this technology more financially accessible.”

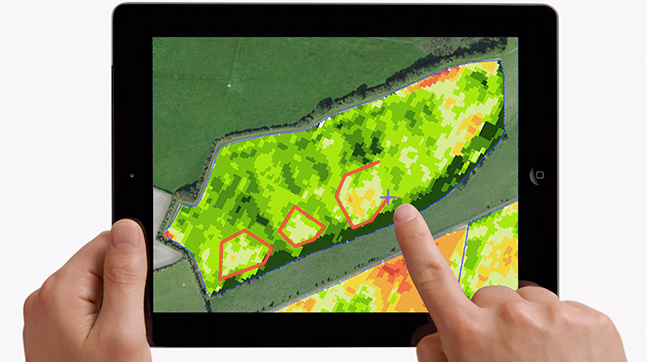

Seed rates were being varied by over 40% of respondents, whilst nitrogen is not as clear cut with 30% being applied using satellite imagery and 20% by tractor mounted imagery, although Mr Wood adds that there is a want to get variable nitrogen applications right as it is the largest input cost on farm.

Interestingly the survey highlighted that yield maps were not being used by over half of farmers. “This is because many growers are not sure what to do with them, and there is a lack of good software to analyse the data.”

However, almost half of all respondents, across all farm sizes, agreed that more technical advice is required for all aspects of variable product applications. “It’s key to remember that the agronomy of the crop hasn’t changed, even though the way that products are being applied is. Once the data is collected it, how it is interpreted is vital to ensure that yields are maximised and the full potential of precision technology is realised,” says Mr Wood.

Shropshire farmer and Nuffield scholar Andrew Williamson has seen the benefits of this approach on his 346ha arable farm in Shropshire. Having studied how growers across the world are using precision technology, Mr Williamson is clear that precision agriculture can only work when based on good agronomy.

“We make use of variable rate applications for seed, fertiliser and other inputs as well as yield mapping, auto guidance and sectional sprayer control – but all of this information is used to push the farm to its potential by ensuring that every part of every field is performing at its optimum.”

“For example, it has meant that we have been able to pinpoint the least productive areas and take those out completely – and these are the areas that we manage in HLS which requires a different approach.”