With the launch of the new MF 7300 BETA combines, Massey Ferguson is introducing higher specification, economy and performance to medium to large-scale operators and contractors. These two new conventional harvesters complement the innovative ParaLevel models that made their debut earlier this year.

’The BETA combines, with five or six straw-walkers, offer large to medium scale operators a combination of premium and practical features that provide high capacity, flexibility and performance,’ says Adam Sherriff, Manager ’ Powered Harvesting. ’Massey Ferguson is now introducing new technology and increased cab comfort while maintaining the BETA’s straightforward design and ease of operation.

’Massey Ferguson BETA combines have gained an enviable reputation for low cost of ownership, combined with high harvesting efficiency in a wide range of crops and conditions, which is reflected in their high residual values. The new models continue this legacy of providing maximum durability and longevity and are the ideal machines for those looking to upgrade to benefit from faster, more economical harvesting from an uncomplicated design.’

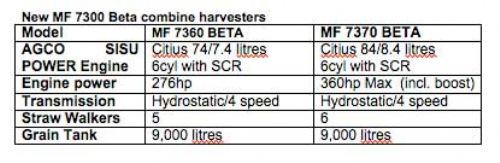

The new MF 7300 BETA combines now feature higher power from exceptionally economical SCR engines, larger grain tanks along with new touch-screen operation with auto-crop setting along and new auto-reel control. Both models are also available with the novel ParaLevel auto-leveling system (see separate press release for details).

New MF 7300 BETA features:

’ Latest advanced AGCO SISUPOWER engines equipped with Generation 2 Selective Catalytic Reduction (SCR) reduce fuel consumption by to 10%

’ New touch-screen terminal providing automatic settings for up to 15 different crops as well as full monitoring and comprehensive control. Integral electronic diagnostics

’ Automatic reel control adjusts speed relative to travel speed

’ High torque and power from uprated,130 litres/min hydrostatic system, which maintains forward speed and increases harvesting efficiency

’ Both 5 & 6 walker models are available with the unique ParaLevel automatic levelling system that compensates for slopes of up to 20%.

’ Both versions can remain within 3.5m for transport with either 800 mm tyres for the five walker and 650 mm tyres for the 6 walker.

Most modern SCR engine offers excellent economy

The new MF 7300 BETA combines are equipped with AGCO SISU POWER’s advanced Citius engines featuring Selective Catalytic Reduction (SCR) exhaust after treatment, which is now well proven in a range of Massey Ferguson tractors and combines.

By treating the exhaust gases after combustion the SCR process does not add any complexity or additional cooling packages, required by mechanical systems. The latest Generation 2 system now also employs a Diesel Oxidation Catalyser (DOC), which includes the AdBlue dosing injector nozzle. From here exhaust gases receive further treatment by SCR Catalysers and ’slip cats’.

Using SCR and AdBlue Diesel Exhaust Fluid (DEF) after treatment allows engineers to set the engine, as normal, for optimum power and economy, which reduces fuel consumption by up to 10%. The advanced, four valve/cylinder and common rail Citius 7.4 litre, six cylinder generates 276hp in the MF 7360, while the larger MF 7370 has an 8.4 litre version, which develops a maximum 360hp including boost. Economy is further enhanced by tuning the engines to achieve the top roads speed of 25km/hr at 1,900rpm and 20km/hr at just 1,560rpm.

Automatic setting for 15 crops on touch-screen terminal

Both new MF 7300 BETA combines now have electronic control via an advanced CANBus network, which comes with a new C2000 touch-screen terminal with soft keys and scroll wheel to select functions and ’scroll’ through pages. This is mounted conveniently on the end of the operator’s armrest and not only monitors all the main combine functions, but also provides automatic machine setting for 15 different crops.

Now all the operator needs to do is select the crop on the screen and the system automatically places the key components such as the threshing cylinder speed, concave setting and fan speed to default positions. Operators can fine tune these adjustments and save three different customised settings of their own choice. Reel speed is now adjusted automatically in relation to forward speed, which is adjusted through the C2000 terminal.

The new system also improves service and support with three diagnostic procedure levels. The first level allows customers to check their own machines, while the second provides higher level access for dealer staff. With the top, third level, AGCO engineers can carry out a full check of the entire electronic system.

High capacity hydrostatic transmission

Both models also benefit from a new hydrostatic pump, delivering 30% more capacity. This generates higher torque and hydrostatic power, particularly for the ParaLevel version on which 4WD is standard. This helps the combines to climb the steepest slopes have positive steering and balance and increase harvesting efficiency.

Proven, practical system for top performance

The new premium features on the latest MF 7300 BETA combines join the practical and proven systems that have established the harvesters’ performance credentials in a wide range of crops and conditions across Europe.

High capacity starts with an even feed and there is no better header than Massey Ferguson’s renowned PowerFlow, with its moving belts, which is proven to cut table losses and can boost output by up to 73% in oilseed rape. The alternative new FreeFlow header comes in widths of up to 7.6m. Both headers provide an even crop feed to the Power Feed Roller at the bottom of the crop elevator, which ensures the intake feeds across the entire cylinder width.

The 600mm diameter Hi-Inertia cylinder, which is 1,340mm wide on the five-walker MF 7360 BETA and 1,600mm wide on the six-walker MF 7370 BETA offers flexible threshing for all crops and conditions. The concave uniquely has differential spacing tight at the front for more aggressive threshing and wider at the back for increased separation, It can be electrically adjusted - front and rear individually ’ via buttons in the cab to obtain maximum threshing capability balanced with throughput.

The Multi Crop Separator (MCS) system, behind the cylinder and concave, provides a rotary separator to deal with longer straw and higher yielding crops for enhanced separation. Uniquely, the concave can be taken out of action if really dry conditions are experienced to preserve the straw and maintain the sample. The 4.3m long straw walkers have four steep steps and 210mm high ’Active Walls’, which increase the open area providing a total separation area of 6.7m’ on the five-walker model and 8m’ on the six-walker.

Excellent cleaning from the large grain pan with high dividers and optimised air flow results in a superb sample in the 9,000 litre capacity grain tank (8,600 litre on ParaLevel version). This is fitted with electrically opening lids, which are waterproof against light showers.

Innovative ParaLevel auto-level system

The innovative Massey Ferguson ParaLevel system provides automatic levelling across slopes of up to 20%, using a completely new parallelogram linkage. The compact and clever system connects the front wheel hubs to the chassis via a lower triangular-shaped bracket and a link arm above ’ forming a parallelogram shaped linkage.