Elanco is centring its 2020 Layer Conference on shaping the future of food safety, specifically Salmonella protection throughout the entire food chain.

Salmonella is one of the top foodborne bacterial diseases worldwide with eggs and egg-based products still the primary cause of salmonella related illnesses.

It’s widely accepted that there is no single measure to control salmonella and instead, a holistic industry commitment and approach is needed.

Whilst successes have been enjoyed in the past, it’s not enough to rely on these to secure a successful future for the industry.

Continuing to strive to improve best practice standards as a means of reducing Salmonella outbreaks in the long-term is imperative.

The Lion Code has been in place since 1998, in which time billions of Lion Code eggs have been tested and sold.

It is seen as the quality stamp by producers, packers and retailers alike and Mark Williams from the British Egg Industry Council (BEIC) will be hosting a session at the conference to share how the Lion Code is continuing to raise the bar.

Whilst the Lion Code is still seen as an industry standard and plays a vital role, further protocols and traceability are crucial to ensure Salmonella prevention.

Officially launching at the Layer Conference taking place on 24 September is Elanco’s new Food Safety Program (FSP), which was initially introduced in 2016 to bring another dimension to the traceability of the egg, from pullet to plate.

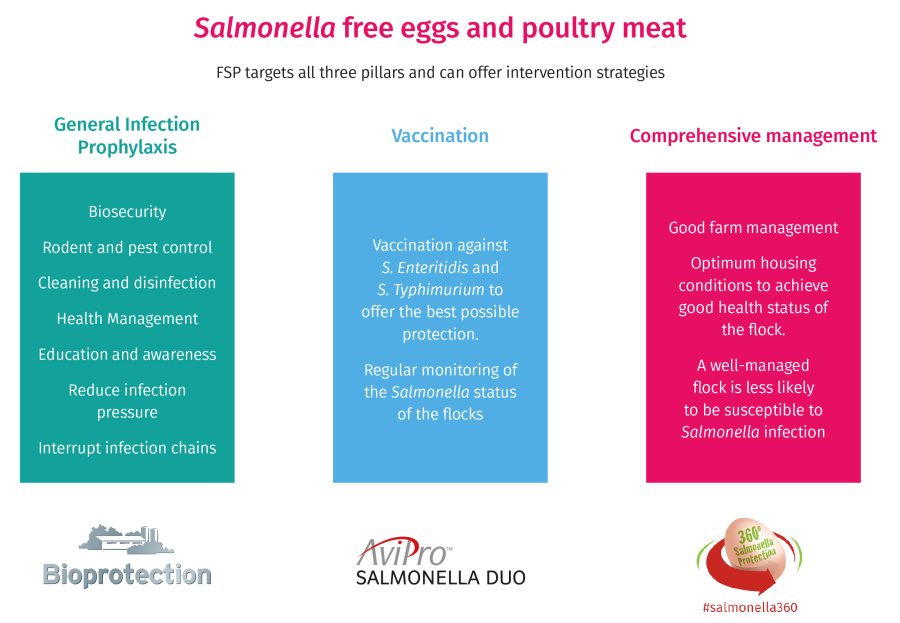

The FSP is an integrated concept combining on-site audits, assessment, calculations and follow up actions. By assisting businesses in understanding and improving their food safety protocols, focussed on Salmonella protection, the FSP will reassure retailers and the public that the industry continues to innovate to ensure Salmonella safety and prevention.

An integrated Salmonella prevention programme starts with the bird. Protecting and building bird immunity from a young age via vaccination is essential and forms the basis for the health of the egg.

Answering the question ‘How does a vaccine make a difference?’ is one of the topics that will be covered at the conference as it’s imperative that we as an industry understand the importance of vaccinations.

Prevention of Salmonella infection has the best chance of being managed successfully through an “integrated approach”. All potential transfer sources of Salmonella to poultry (feed, day-old chicks, water, staff, etc.) should be carefully considered when you evaluate intervention strategies against Salmonella and biosecurity is crucial – Robert Gooch from the British Free Range Egg Producers Association (BFREPA) will be exploring the challenge of biosecurity on farm at the conference.

Also part of this approach is the role of auditing where Dave Hodson from Rosehill will be taking delegates through his advice on what a good audit looks like.

As part of the FSP, there are essentially four steps to achieving integrated Salmonella prevention:

Measure

This stage involves an on-site visit from the Elanco team to understand and identify possible risk areas that may lead to Salmonella contamination.

An analysis of the various risk areas will be carried out from which a Food Safety Index (FSI) score will be calculated. The FSI is at the centre of the FSP and is a score that has been developed to determine the relative risk of Salmonella on farm.

By facilitating measurement of risk factors, the FSI can be used to guide interventions to minimise the risk of Salmonella to a flock by quantifying risks and implementing solutions.

Risks are identified and ranked using our integrated questionnaire and weighting system. For each area, the risk is calculated and ranked into one of three risk categories:

high risk, increased risk and potential risk.

Understand

This stage involves identifying and documenting points of control with the Food Safety Index (FSI) - developed in conjunction with many producers and veterinary professionals.

Using questions and the field visit in stage one, the responses and their relative impact determines the index score. The index is presented as a percentage; the higher the percentage, the lower the risk.

The FSI will rank the scores and identify areas of potential risk so the farm can focus on these and improve where necessary.

Improve

Once risks have been assessed, whether high, increased or potential, further discussions, and where necessary, workshops and training sessions would be planned in co-ordination with the producer and their teams, working together to review the gaps in protocols and how these can be controlled and corrected.

The discussions will focus on the farm’s lowest scores in the index and their influencing factors. Recommendations will be made and can be discussed further.

A follow up assessment is recommended to monitor the progression and impact of interventions.

Monitor

The FSP is a continual loop whereby everything is monitored to avoid complacency. Analysis and actions to test the effectiveness of the implemented solutions is critical to ensure the recommendations are well implemented by the farm staff.

On-going monitoring will be designed with the producer management team taking into account factors that may have an impact on success i.e. finance, time etc.

The monitoring will focus on specific risk factors identified by the FSI, an increased index score will reflect successful implementation.

The FSP also allows benchmarking between customer farms, both geographically and over time. This will give an overview of farm status before and after implementation of improvements.

Overall, the aim of the Elanco Food Safety Program is to support farms to become Salmonella-free and remain Salmonella-free in the long term.

It’s a science-based, internationally tested tool, grounded in real world application – practical and pragmatic in its approach with the unique algorithm that will generate a bespoke food index score for your farm.

The FSP follows a systematic process that works to protect everything around the bird through each stage of poultry production and highlighting where gaps need to be controlled:

• Evaluate the risks related to Salmonella contamination at the different stages of poultry production

• Support risk reduction by providing tailored recommendations and individual solutions, quantifying critical points on farm through evidence-based risk assessment

• Benchmarking of farms to drive continuous improvement with specific areas of focus

• Analyse resultant data to identify areas of risk across the entire producer base

• Establish a monitoring programme to improve current situations

• Support farms to aim to become Salmonella-free or remain Salmonella-free in the long-term

The Elanco Poultry Team are delighted to be launching the Food Safety Program (FSP) at the upcoming 2020 Elanco Layer Conference within the conference theme of Shaping the Future of Food Safety.

Alongside the FSP launch, the virtual event will also offer a full afternoon of presentations and webinars by industry leaders and will be hosted by renowned food and drink broadcaster, Nigel Barden.

To register for the virtual Layer Conference please visit https://web.elanco.com/fsp-pullet-to-plate-register.html.